RECENTLY ADDED PRODUCTS

{{ item.ProductName }}

{{ item.VariantSku }}

QTY: {{ item.Quantity }}YOU DO NOT HAVE ANY ITEMS IN YOUR BASKET

About Us

Call us on 01942 620062

{{ item.VariantSku }}

QTY: {{ item.Quantity }}

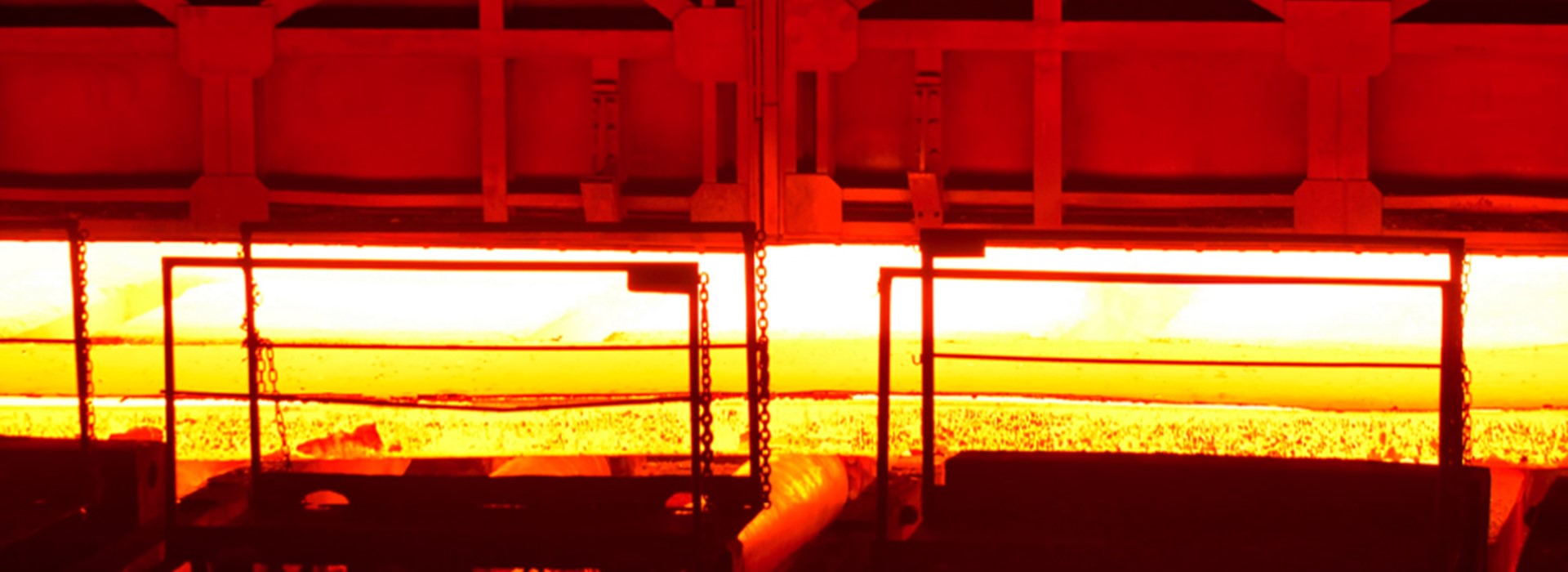

Thermal Hire was formed in 1974 and entered the field of thermal heating in a modest way. At first the Company specialised in the manufacture and hire ofgas and oil fired combustion equipment. This provided experience in the manufacturing techniques and management control systems as well as gaining a foothold in the thermal and metal heat treatment industries.

Thermal Hire head office is based at Wigan and is where the majority of the Management, Administration, Sales, Technical, Quality and Health and Safety departments are based.

We also carry out Heat Treatment Site Services, Equipment Hire, Equipment Manufacturing and Furnace Treatments at this facility.

| TYPE | WORKING DIMENSIONS | CAPACITY | MAX TEMP | STATUS | |

|---|---|---|---|---|---|

| FURNACE 1 | Top Hat/Gas Fired | N/A | N/A | N/A | |

| FURNACE 2 | Top Hat/Gas Fired | 2.8m L x 0.8m W x 1.3m H | 4 Tonnes | 1200°C | |

| FURNACE 3 | Bogie Hood/Gas Fired | 6.95m L x 3.95m W x 2.5m H | 20 Tonnes | 900°C | |

| FURNACE 4 | Top Hat/Gas Fired | 3.8m L x 2.8m W x 2.1m H | 25 Tonnes | 1250°C | |

|

Overhead Craneage: 30 & 40 Tonnes |

Area: 22,000 Square Feet |

Firing Frequency 7 Days Per Week |

|||

Our Hartlepool factory houses twenty two furnaces ranging in size from 2.5m x 1.2m x 1.2m to 15.2m x 4.6m x 3.7m. Six of the furnaces are complimented by water and polymer quench facilities and have state-of-the-art automatic control for furnace operation and transfers.

We also have a 16m x 3m fully-enclosed shot-blasting unit and a band saw on site capable of cutting up to 600mm diameter solid bar.

| TYPE | WORKING DIMENSIONS | CAPACITY | MAX TEMP | STATUS | |

|---|---|---|---|---|---|

| FURNACE 1 | Roll Aside Bogie Hearth/Gas Fired | 15.5m L x 4.6m W x 3m H | 100 Tonnes | 1200°C | |

| FURNACE 2 | Top Hat/Gas Fired | 10.6m L x 3.1m W x 2.8m H | 100 Tonnes | 1200°C | |

| FURNACE 3 | Top Hat/Gas Fired | 6.1m L x 2.4m W x 2m H | 100Tonnes | 1400°C | |

| FURNACE 4 | Top Hat/Gas Fired | 4.0m L x 2.5m W x 1.5m H | 20 Tonnes | 1200°C | |

| FURNACE 5 | - | - | - | - | |

| FURNACE 6 | Top Hat/Gas Fired | 2.5m L x 1.2m W x 1.2m H | 2 Tonnes | 1200°C | |

| FURNACE 7 | Top Hat/Gas Fired | 10.6m L x 3.1m W x 1.6m H | 100 Tonnes | 1200°C | |

| FURNACE 8 | Top Hat/Gas Fired | 14m L x 3.4m W x 2.7m H | 100 Tonnes | 1200°C | |

| FURNACE 9 | Top Hat/Gas Fired | 14m x L 3.4m W x 2.7m H | 100 Tonnes | 1200°C | |

| FURNACE 10 | Top Hat/Gas Fired | 12.1m L x 3.6m w x 1.5m H | 100 Tonnes | 1300°C | |

| FURNACE 11 | Top Hat/Gas Fired | 3.95m L x 3.0m w x 1.35m H | 20 Tonnes | 1200°C | |

| FURNACE 12 | Top Hat/Gas Fired | 12m L x 3.1m W x 1.8m H | 100 Tonnes | 1300°C | |

| FURNACE 13 | Top Hat/Gas Fired | 13.6m L x 5.0m W x 3.7m H | 100 Tonnes | 1200°C | |

| FURNACE 14 | Top Hat/Gas Fired | 7.0m L x 4.0m W x 3.0m H | 50 Tonnes | 1000°C | |

| FURNACE 15 | Bogie Hearth/Gas Fired | 8.6m L x 5.4m W x 3.0m H | 50 Tonnes | 750°C | |

| FURNACE 16 | Front Loading/Gas Fired | 3.2m L x 2.5m W x 0.8m H | 6 Tonnes | 1200°C | |

| FURNACE 17 | Front Loading/Gas Fired | 3.2m L x 2.5m W x 0.8m H | 6 Tonnes | 1200°C | |

| FURNACE 18 | Front Loading/Gas Fired | 3.2m L x 2.5m W x 0.8m H | 6 Tonnes | 1200°C | |

| FURNACE 19 | Front Loading/Gas Fired | 3.2m L x 2.5m W x 1.2m H | 6 Tonnes | 1200°C | |

| FURNACE 20 | Front Loading/Gas Fired | 12.45m L x 3.2m W x 2.0m H | 20 Tonnes | 1200°C | |

| FURNACE 21 | Front Loading/Gas Fired | 12.45m L x 3.2m W x 2.0m H | 20 Tonnes | 1250°C | |

| FURNACE 22 | Top Hat/Electric | 1.9m L x 1.35m W x 1.15m H | 1 Tonne | 1000°C | |

| FURNACE 23 | Test Oven/Electric | 0.7m L x 0.7m W x 0.6m H | 250kg | 800°C | |

|

Quenching Facilities: Type: Water Quench and Polymer Quench Working Dimensions 12.45m x 3.0m x 4.1m 20 tonnes Each Type: Water Quench and Polymer Quench Working Dimensions 4.0m x 4.0m x 3.2m 6 Tonnes Each |

|||||

|

Overhead Craneage: 32 & 45 Tonnes |

Area: 150,000 Square Feet |

Firing Frequency 7 Days Per Week |

|||

If you would like more information about any of Thermal Hires’s products or services, please complete the enquiry form below. Alternatively, you can call us at our Wigan, Hartlepool or Falkirk locations, details below.

Unit 12, Pagefield Industrial Estate

Miry Lane

Wigan, Lancashire

WN6 7LA

Tees Bay Business Park

Brenda Road

Hartlepool

TS25 2BU

Unit 9, Castle Court

Bankside Industrial Estate

Falkirk

FK2 7UU