RECENTLY ADDED PRODUCTS

{{ item.ProductName }}

{{ item.VariantSku }}

QTY: {{ item.Quantity }}YOU DO NOT HAVE ANY ITEMS IN YOUR BASKET

About Us

Call us on 01942 620062

{{ item.VariantSku }}

QTY: {{ item.Quantity }}Thermal Hire has vast experience using flexible ceramic heating pads to perform a multitude of local heating operations including;

Whether you have a single 1" butt weld preheat, a full circumference closing seam of a vessel or a major plant maintenance shutdown Thermal Hire has the capability and experience to meet your requirements.

Thermal Hire's original area of expertise, the company has now completed over 2000 gas-fired heat treatments worldwide. Contracts completed include refractory dryouts in Iceland and full vessel PWHT in South Africa to temporary furnace construction in Barrow and blast furnace maintenance in Serbia.

Thermal Hire's expertise in local gas-fired heat treatment is second to none.

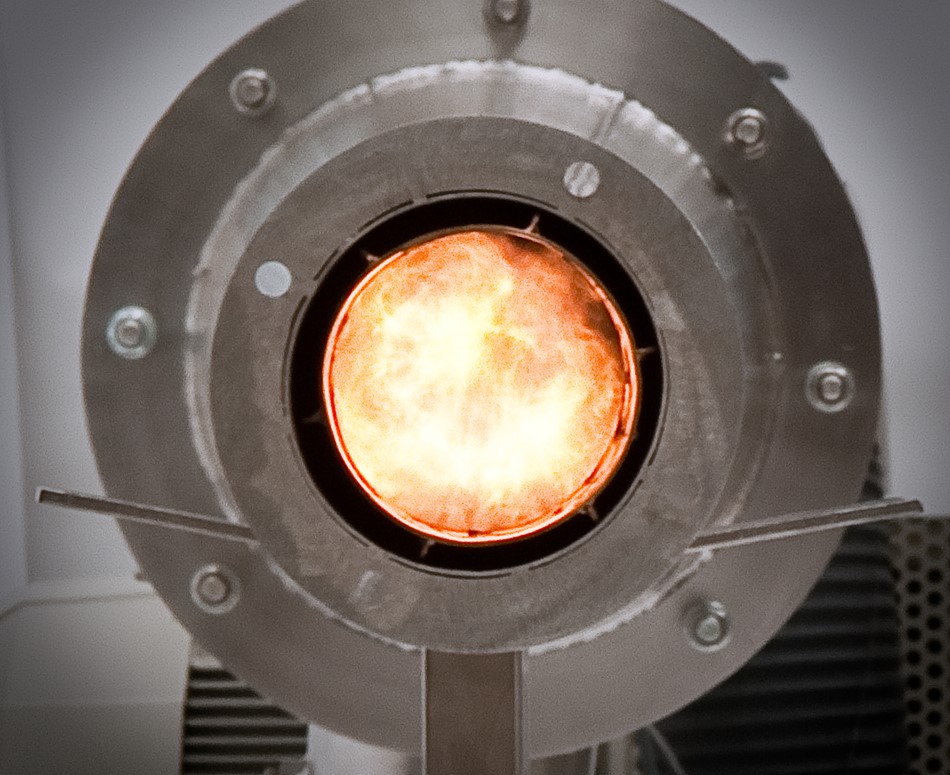

Induction heat treatment has been around for over 40 years. Heating is achieved without any direct physical contact and finds use in almost every industry where metals are used, be it in alloying, metal forming, tempering, hot working or shrink fitting. The technique is capable of heating materials at rates of temperature rise not normally associated with other methods, such as electrical resistance or gas heating, with a high degree of efficiency.

The induction heat treatment process relies on induced electrical currents within the material to produce heat. As there is no or limited physical contact, there are potential advantages in production. For example, there is less risk of contamination, a simpler heating arrangement and less insulation may be required.

If you would like more information about any of Thermal Hires’s products or services, please complete the enquiry form below. Alternatively, you can call us at our Wigan, Hartlepool or Falkirk locations, details below.

Unit 12, Pagefield Industrial Estate

Miry Lane

Wigan, Lancashire

WN6 7LA

Tees Bay Business Park

Brenda Road

Hartlepool

TS25 2BU

Unit 9, Castle Court

Bankside Industrial Estate

Falkirk

FK2 7UU